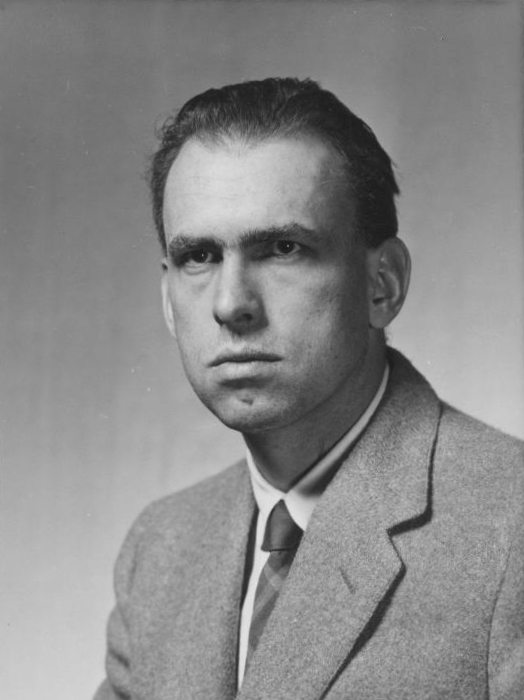

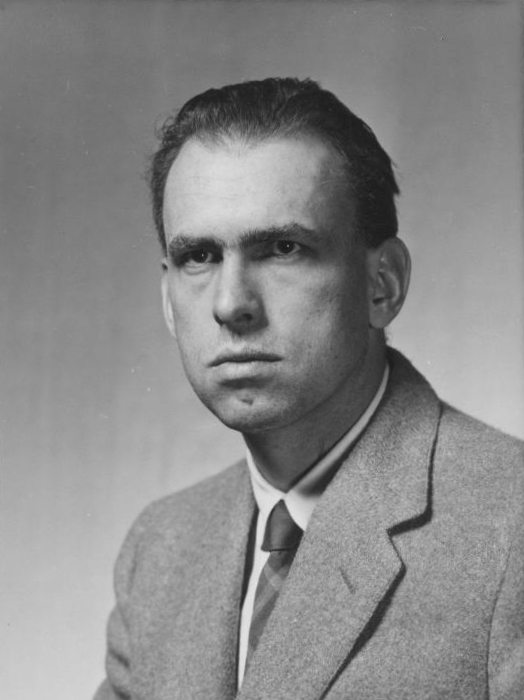

Professor Peter Griffith died on March 5, 2022, at the age of 94. Pete served in the heat transfer laboratory of the Massachusetts Institute of Technology for more than 60 years. Pete's research encompassed two-phase flow, nucleate boiling, dropwise condensation, heat transfer to supercritical fluids, water hammer, and nuclear reactor safety. He also consulted extensively on thermal and nuclear engineering

Pete joined the heat transfer lab as a doctoral student in 1952, and he went on to become the longest serving faculty member in the lab's 150-year history [1]. The heat transfer lab is in a basement, but Pete nevertheless kept his office inside this lab, rather than taking a more sumptuous office on MIT's Great Courtyard. As a result, Pete engaged with every student who worked in the lab up to 2012. He provided technical advice, experimental guidance, mentorship, and critical feedback without hesitation, no matter who was the student's actual advisor. His influence, accordingly, was enormous.

Pete Griffith was born in London, England in 1927, and he grew up in Huntington, Long Island, in New York state. As a child, Pete was known as a tinkerer, even building forges, and he spent much time in the woods near his home [2]. Pete enrolled at New York University in 1945, immediately after high school, but was drafted into the US Army Air Corps one year later. He served eighteen months as a finance clerk typist in Iceland, Greenland, and Labrador, then returning to NYU and receiving his BME in 1950 [3]. He took a master's degree at the University of Michigan in 1952. Pete then came to MIT for ScD work, completing his dissertation The dynamics of bubbles in nucleate boiling in 1956 under the guidance of Warren Rohsenow. Upon graduation, Pete immediately joined the MIT mechanical engineering faculty as an assistant professor.

One of Pete's earliest goals was to understand the regimes of two-phase flow in pipes. Working with his student Graham Wallis, Pete built an 18 ft tall Plexiglas pipe through which he flowed a mixture of air and water in varying proportions [4]. The tube enabled direct visualization of the flow patterns at different gas/liquid flow rates, and with associated pressure taps, he could map both the flow regime and the head loss that accompanied it. Pete spent countless hours making small adjustments to the flow rates and noting the effect [5]. He mapped out the conditions leading to bubbly flow, to slug flow, and to misty annular flow. Pete was to return to large-scale pipe flow experiments many times during his career. At a smaller scale, with his student Mikio Suo, he mapped flow patterns in capillary tubes, combining dimensional analysis with data for combinations of water or heptane with nitrogen, air, or helium [6].

These flow regime maps were of interest for their importance to flow boiling, which was a major focus of the MIT heat transfer lab at that time, especially in connection with nuclear reactor cooling. The metal tubes used in boiling work were of course opaque; and so Rohsenow referred to Pete's substitution of low temperature gas-liquid flow in a transparent pipe as "Take a peek” [7].

During the 1960s and early 1970's, Pete's research also encompassed nucleate boiling, film and dropwise condensation, and heat transfer under supercritical flow in tubes. In 1968, Pete and his student Bharat Shiralkar reported the first observations of degraded heat transfer in supercritical CO2 using a flow loop they built in the heat transfer lab [8]. Degraded heat transfer had previously been seen in water and a few other fluids but seemed absent from CO2 experiments, which had until then used relatively high inlet temperatures. This paper is a reminder of the early state of heat transfer research in supercritical fluids at the time. The literature was divided as to whether thermal conductivity did or did not spike at the pseudocritical temperature, many regarded this now confirmed phenomenon as merely a measurement error caused by large density differences. Additionally, the complex dependence of heat transfer behavior on the "path” taken past the critical point was still being explored. Pete presented this research at the 10th AIChE-ASME Heat Transfer Conference in 1968 and received the conference's Best Paper Award for it [9]. The paper was later published in the Journal of Heat Transfer.

With his student Clark ("Corky”) Graham, Pete measured the drop size distributions during dropwise condensation of water onto treated copper [10]. They reported nucleation site densities of 200x106/cm2, and with a model they determined that the dominating thermal resistance shifted from liquid resistance to interfacial resistance as the atmospheric pressure was reduced. This paper remarks "The picture which emerges is just as complicated as the boiling picture, and just as difficult to reduce to an engineering correlation.”

Pete's work on nucleate boiling mechanisms also proceeded through a combination of experiments and modeling. His two-part paper with Chi-Yeh Han [11] develops very detailed transient conduction models for the liquid surrounding a growing bubble and compares them to his characteristically rigorous measurements. These bubble growth data were acquired using high-speed photography through a so-called "fluid crystal”, an enclosing glass box filled with the same liquid as the test section to eliminate image distortions caused by refraction. The boiling surface preparation is documented in excruciating detail, for example noting that the diamond compound "should be placed at the center of the grinding wheel and diluted by kerosene.” The prediction of the data by the theory is excellent.

Yet, this paper notes the inherent randomness of the boiling process and states that the good agreement is "partly fortuitous.” Additional remarks state that while the theory assumes a periodic bubble departure "this is hardly the case” and that "the procedures used here are far too complicated to be of use in prediction in a practical problem.” Thus, this excellent and well-cited paper also reveals the tension Pete saw between highly complex modeling and the problems engineers actually need to solve.

Pete once characterized overcomplicated theories this way: Two kids who live next door to each other each build a tree house. Then they string up a tin-can telephone between the treehouses. One kid talks into a can while the friend listens to the other can, and after speaking the first kid leans out of the treehouse and yells "Did you hear me?” To Pete, models that served only to show off a theoretical principle were as unhelpful to engineers as the tin-can phone was for children's communication [12].

This impatience with unnecessary theoretical complexity permeated Pete's teaching at MIT. He emphasized that students should understand the size of physical variables (say, the relative magnitudes of thermal resistances) and that they should focus on picking out primary phenomena and modeling them in a straightforward way. He applied this philosophy in teaching the MIT two-phase flow class. Gone were the repetitive recitations of formal definitions and complex models for steam-water mixture behavior; rather, Pete created practical demonstration apparatuses (some being similar to Rube Goldberg machines), and he then challenged students to deduce the principal physical phenomena at play. Similarly, he once advised a young colleague not to "teach procedure” for solving problems [12], since procedures (graphical integration, say) are constantly replaced by more efficient, up-to-date techniques (numerical procedures, say).

Similarly, Pete's doctoral exam questions never tested how much math a student could do. Instead, he'd typically adapt a problem from his consulting work and ask candidates to try to explain what was going on. He questioned students with a light touch—and many jokes—once saying: "You don't find out how much someone knows by scaring them to death” [13]. Yet, despite his easygoing manner, Pete could make hard judgments. He could be tough with colleagues and could draw firm lines with students.

In the 1970s and later, nuclear reactor safety came to occupy a large portion of Pete's time. He consulted for both the US Energy Research and Development Administration and the US Nuclear Regulatory Commission (NRC), as well as many companies and several federal labs. At the NRC, Pete was an often-sought voice on the extramural advisory committees that guided technical investigations of critical regulatory issues. His consulting encompassed diverse topics in thermohydraulics, such as liquid metal fast breeder reactors, natural circulation, spallation, advanced light water reactor design, and critical heat flux phenomena.

Pete's final papers, published after his retirement in 1997 with his student Marc Hodes and Professor Kenneth A. Smith, dealt with salt fouling by buoyancy-driven supercritical water flows [14]. Pete spotted this research question while visiting a start-up company that was developing supercritical water oxidation as a low-temperature alternative to incineration [15]. Long after Pete retired, he was still consulting for the founder of this company, on sludge management for the city of Orlando, Florida.

Pete's excellent research, and his practicality, were widely respected in the heat transfer community. He received the 1975 ASME Heat Transfer Memorial Award "for his outstanding contributions to the art of heat transfer in two-phase flow, boiling, and condensation.” Similarly, a 1984 Journal of Heat Transfer paper by Pete and his student Robert Bjorge received the best paper award of the ASME Heat Transfer Division and was selected for the 1986 Melville Medal, ASME's highest honor for an original research paper. This elegant paper, not quite six pages long, provides an experimentally validated analytical model for the onset of water hammer caused by steam bubble collapse in a stratified horizontal pipe [16]. Remarkably, the model required no empirical fitting beyond a single adjustment to the heat transfer coefficient correlation. The simplicity of work stands in sharp contrast to the complex models that Pete published in the early 1960s.

During his long career, Pete supervised 39 doctoral dissertations, 91 master's theses, and 78 bachelor's theses, including many nuclear engineering students. He started teaching at MIT as an instructor in 1954 and continued until he retired. Pete taught across the full breadth of the mechanical engineering curriculum, including many semesters in introductory solid mechanics. His passion, however, was experimentation. From 1962 to 1996, he led a senior level lab subject that gave students a few weeks to work on each of several different experiments. These experiments involved diagnosing, explaining, and modeling the behavior of thermal systems, some steam-operated, and most drawn directly from Pete's work as a consultant.

When Pete retired, the mechanical engineering department created an endowed award, The Peter Griffith Prize for Outstanding Undergraduate Experimental Work, to honor his contributions to teaching experimentation over so many years. Pete's excitement in creating new knowledge and advising students was such that he continued to engage in research and teaching for many years after retiring.

Pete kept his home life well separated from his job. According to his daughter, Kat Griffith, he never brought MIT work to his house [17]. His time at home went entirely to family life. One may wistfully observe that, in this way, Pete was quite unlike most professors, then or now.

Pete commuted between home and work on his bicycle, which he rode through Belmont and Cambridge every day, all year. His bike was not a fancy racing bike or a techy recumbent, but simply a sturdy upright bike with a cargo rack over the back wheel. And, whenever time allowed, Pete retreated to his cabin on 100 acres of undeveloped land in Vermont, where he'd spend much time in the woods, cutting trees, clearing trails, and collecting mushrooms.

In addition to his daughter Kat, Pete is survived by his son-in-law, Soren Hauge, his stepdaughter and son-in-law, Sara and Stephen Young, and five grandchildren.

|

|